Green Technology

Energy efficiency is a commitment to us and a duty we owe towards future generations to pursue thorugh our green home lifts.

All NOVA Elevators green home lifts are designed and manufactured to minimize its impact on the environment and optimize energy consumption, while ensuring the highest performance levels.

We create green home lifts with a refined and elegant design and attention to energy efficiency and product quality.

Eco-friendly technology

Energy efficiency begins at NOVA Elevators factory, with the disposal and recycling of production waste, continuing with the manufacture of green home lifts with reduced environmental impact.

Green homelifts

Our homelifts are designed to comply with the “green” concept established by the European Union, certified in A Class according to the directive German VDI 4707.

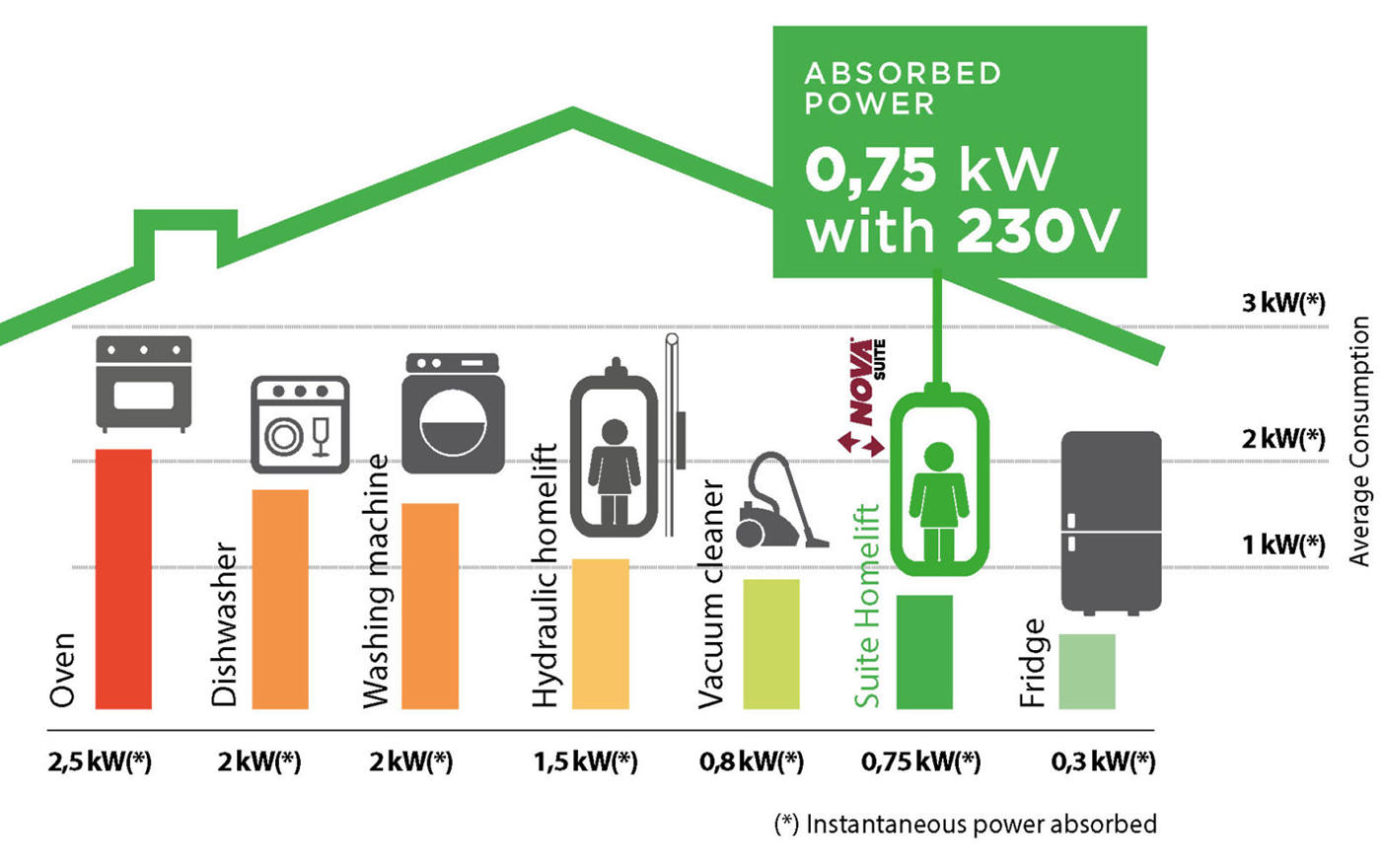

The Suite home lift equipped with the gearless drive, has minimum consumption (0.75 kW at 230 V … less than vacuum cleaner!), thanks to a system which reduces the energy needed when the elevator is in stand-by.

Energy efficient homelifts

The traction model with a load capacity of 300 kg requires only 100Kw/H a year, with a consumption of only 0.75 kW … less than a vacuum cleaner!

The gearless motor can be equipped on all Suite green home lifts and it can work in relation to the cabin load capacity, so that if the cabin is empty, the unit requires less energy.

When the cabin is not moving, the Suite Lift homelift switches off the system automatically.

The energy consumption can be reduced up to 70% thanks to this system.

What is the gearless drive?

The gearless motor, which NOVA adopts on its green home lifts, is a smart motor, capable of supplying the power according to the feedbacks received during its travel. When the homelift runs with no load in its cabin, the motor will supply a small amount of power whereas, when the cabin is fully loaded, the gearless system is able to optimize energy supply according to the weight.

The movement will therefore be optimized in real time.

The energy efficiency is not only low consumption but also low waste: our metal structures and doors are designed in order to provide thermal insulation and to reduce as much as possible thermal transmittance between different rooms.

Your energy-efficient house

The traction Suite green home lift guarantees energy efficiency to your whole house. The outdoor accessories can be insulated: the outdoor steel structure is insulated with heat-resistant material or thermal glass, with a thermal transmittance rate up to 1.1 W/mqK (in cm). The thermal glass door also grants high insulation levels thanks to magnetic seals and double glass.

NOVA, an eco-friendly factory

NOVA engineers continuously study new technologies aimed at improving energy efficiency not only on our green home lifts, but also of their production plant. This is why NOVA Elevators has chosen to install a 100 kW photovoltaic system, which guarantees the production of 70% of the energy required by our plant, while the remaining 30% is supplied externally from renewable sources.